ISO-9001-Lead-Auditor Exam Dumps - QMS ISO 9001:2015 Lead Auditor Exam

Searching for workable clues to ace the PECB ISO-9001-Lead-Auditor Exam? You’re on the right place! ExamCert has realistic, trusted and authentic exam prep tools to help you achieve your desired credential. ExamCert’s ISO-9001-Lead-Auditor PDF Study Guide, Testing Engine and Exam Dumps follow a reliable exam preparation strategy, providing you the most relevant and updated study material that is crafted in an easy to learn format of questions and answers. ExamCert’s study tools aim at simplifying all complex and confusing concepts of the exam and introduce you to the real exam scenario and practice it with the help of its testing engine and real exam dumps

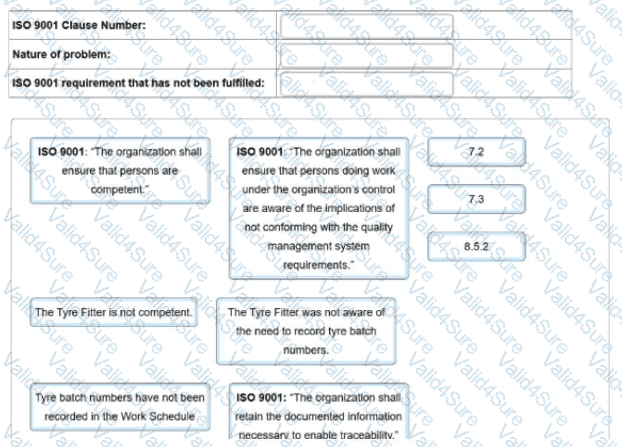

To complete the non-conformity report, click on the blank section you want to complete so it is highlighted in red and then click on the applicable text from the options below. Alternatively, drag and drop the options to the appropriate blank section.

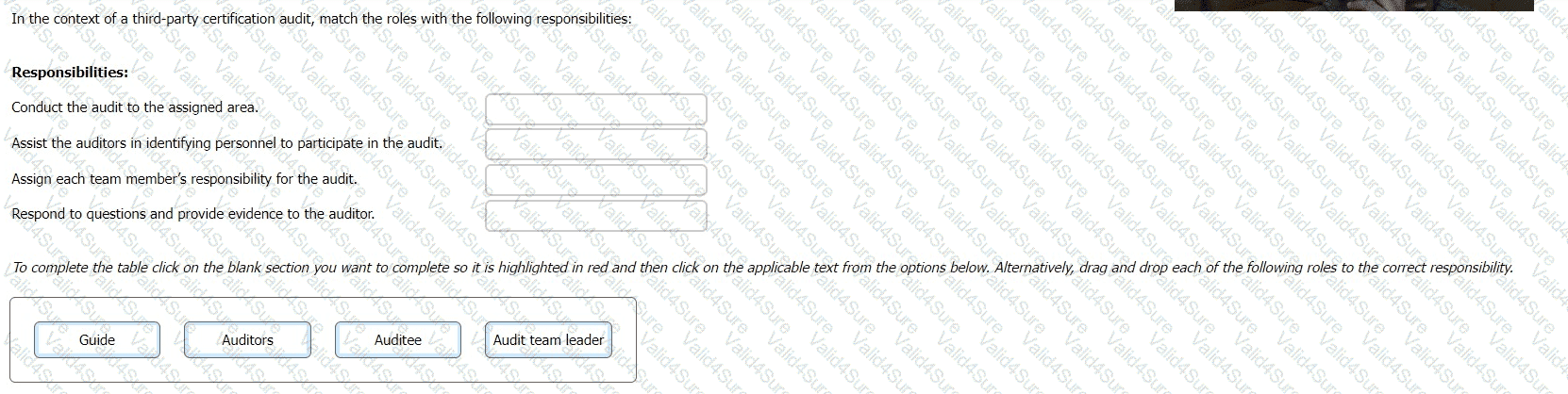

In the context of a third-party certification audit, match the roles with the following responsibilities:

Scenario 5: Mechanical-Electro (ME) Audit Stages

Mechanical-Electro, better known as ME, is an American company that provides mechanical and electrical services in China. Their services range from air-conditioning systems, ventilation systems, plumbing, to installation of electrical equipment in automobile plants, electronic manufacturing facilities, and food processing plants.

Due to the fierce competition from local Chinese companies and failing to meet customer requirements, ME's revenue dropped significantly. In addition, customers' trust and confidence in the company decreased, and the reputation of the company was damaged.

In light of these developments, the top management of ME decided to implement a quality management system (QMS) based on ISO 9001. After having an effective QMS in place for over a year, they applied for a certification audit.

A team of four auditors was appointed for the audit, including Li Na as the audit team leader. Initially, the audit team conducted a general review of ME's documents, including the quality policy, operational procedures, inventory lists, QMS scope, process documentation, training records, and previous audit reports.

Li Na stated that this would allow the team to maintain a systematic and structured approach to gathering documents for all audit stages. While reviewing the documented information, the team observed some minor issues but did not identify any major nonconformities. Therefore, Li Na claimed that it was not necessary to prepare a report or conduct a meeting with ME's representatives at that stage of the audit. She stated that all areas of concern would be discussed in the next phase of the audit.

Following the on-site activities and the opening meeting with ME's top management, the audit team structured an audit test plan to verify whether ME’s QMS conformed to Clause 8.2.1 (Customer Communication) of ISO 9001.

To do so, they gathered information through group interviews and sampling. Li Na conducted interviews with departmental managers in the first group and then with top management. In addition, she chose a sampling method that sufficiently represented customer complaints from both areas of ME's operations.

The team members were responsible for the sampling procedure. They selected a sample size of 4 out of 45 customer complaints received weekly for electrical services and 2 out of 10 complaints for mechanical services.

Afterward, the audit team evaluated the evidence against the audit criteria and generated the audit findings.

After reviewing the documented information, Li Na claimed that it was not necessary to report the minor nonconformities that were identified; instead, they would be discussed in the next audit phase. Is this acceptable?

ABC is a fast food shop that receives orders by phone or the internet. The normal menu includes 15 different types of hamburgers; however, in the

last two days, due to a shortage of a special type of meat, they can only prepare six of the 15 varieties.

You are performing a third-party audit of ABC; you observed that the menu offering food on the website is still the normal one, with 15 different

hamburgers. During a 30-minute period, you observed several customers reluctantly accepting other than the hamburger they preferred. You decided

to raise the following nonconformity as follows:

"There is evidence that ABC has not reviewed the ability to provide customers the offered products".

The restaurant manager does not accept the nonconformity. She says that ABC had an extensive training programme for all personnel, which you have already seen when auditing Human Resources. This shortage of some hamburgers cannot be considered a management system failure.

Which one would be your answer from the following options?

What must the auditor consider in order to mitigate audit risks and obtain reasonable assurance?

Which quality management principle does an organization fulfill when it assesses risks, consequences, and impacts before taking action?

Noitol is an organisation specialising in the design and production of e-learning training materials for the insurance market. During an ISO 9001 audit of the development department, the auditor asks the Head of Development about the process used for validation of the final course design. She states that they usually ask customers to validate the product with volunteers. She says that the feedback received often leads to key improvements.

The auditor samples the design records for a recently completed course for the 247 Insurance organisation. Design verification was carried out but there was no validation report. The Head of Development advises that this customer required the product on an urgent basis, so the validation stage was omitted. When asked, the Head estimates that this occurs about 50% of the time. She confirms that they always ask for feedback and often make changes. There is no record of feedback in the design file for the course.

The auditor decides to review the training course design process in more depth.

Select three options that provide a meaningful audit trail for this process.

A Health Trust has contracted with Servitup, a catering services company that has been certified to ISO

9001 for one year. It provides services to 10 small rural hospitals in remote locations involving the

purchase and storage of dry goods and fresh produce, preparing meals and loading heated trolleys for

ward service by hospital staff. You, as auditor, are conducting the first surveillance audit at one site with

the Deputy Catering Manager (DCM).

DCM: "I apologise for the absence of the Catering Manager. He has called in sick today and we are really

short of staff."

You: "I see. It really shouldn't affect the QMS so the audit can progress as normal."

DCM: "The Catering Manager set up the system. I'm afraid I'm not as familiar with it as he is."

You: "OK, let's start with the Quality Policy. What are the main issues for the QMS here?"

DCM: Give me a minute. I need to look at the Quality Policy on the noticeboard in his office.

You find that two internal audits have been carried out in the first year by the Catering Manager. One of

them indicates that complaints from patients are increasing in number, mainly due to food being served

too cold. The DCM comments that the trolley thermometer is often unreliable.

Which two of the following actions would be "correction" in dealing with the complaints?